HM circular saw blades for the first wood processing

For

cross cutting of:

- softwood

- hardwood

- exotic wood

Body blades steel

Steel used for the construction of the body blades is hot or cold rolled.

There are two main categories:

- 80CrV2: for medium / high applications with high stress

- 75Cr1: for standard applications

Teeth

The choice of high quality carbide, to be used for cutting different materials, is directed towards various types of quality of micro / fine / medium grain inserts, to ensure greater durability of the circular blade, greater resistance to shocks and limited wear of the tooth.

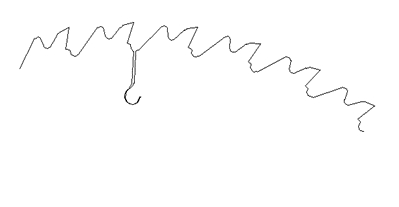

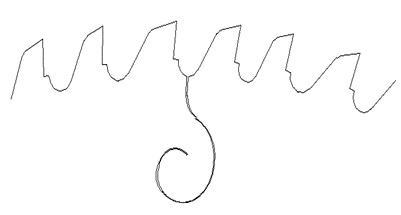

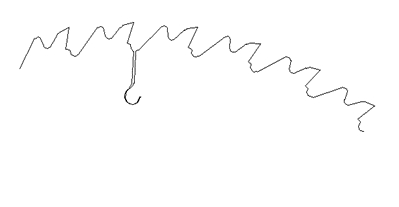

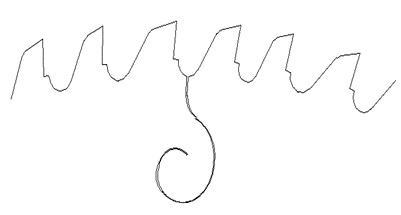

The mainly used cutting geometries are alternate and trapezoidal-flat.

The cutting thickness is increased and radial and tangential angles are accentuated to have a better penetration and a greater dumping of the chip, avoiding the lateral kneading of the body blade.

- Speed of use 50-80 m / s

- High feed cutting process

- Suggested pitch according to the section and quality of the material to be cut

- Maximum cutting performance

We produce all sizes, number of teeth and thickness

Diameter: from 30 mm up to 2200 mm

Thickness: from 1 mm up to 15 mm

The following table shows just a few of the most commonly used diameters, number of teeth and thickness

| Type GM |

| Diameter |

ST |

SC |

Teeth |

| 550 |

4,8 |

3,4 |

48-60-72-96 |

| 600 |

5,0 |

3,5 |

48-60-72-96 |

| 650 |

5,0 |

3,7 |

48-60-72-96 |

| 700 |

5,0 |

3,7 |

48-60-72-96 |

| 750 |

5,5 |

4,0 |

48-60-72-96 |

| 800 |

6,0 |

4,5 |

48-60-72-96 |

| 900 |

6,5 |

5,0 |

54-72-84-96 |

| 1000 |

7,5 |

6,0 |

54-72-84-96 |

| 1100 |

7,5 |

6,0 |

54-72-84-96 |

| 1200 |

9,0 |

7,0 |

60-72-84-100 |

| 1300 |

9,0 |

7,0 |

60-72-84-100 |

| 1400 |

9,0 |

7,0 |

60-72-84-100 |

| 1500 |

9,0 |

7,0 |

60-72-84-120 |

| 1600 |

9,0 |

7,0 |

60-72-90-120 |

| 1700 |

9,0 |

7,0 |

60-72-90-120 |

| 1800 |

9,5 |

7,0 |

60-72-90-120 |

| 1900 |

9,5 |

7,0 |

72-96-120 |

| 2000 |

9,5 |

7,0 |

72-96-120 |

| 2100 |

10,5 |

8,0 |

72-96-120 |

| 2200 |

10,5 |

8,0 |

72-96-120 |

(ST = cutting thickness, SC = body blade thickness)

Central bore and pin-holes available for all types of machines.

Execution of different sharpening geometries, use of various teeth quality and coatings.

Our technical office remains at your disposal for every application needs.